Martian Banana Beam

For: Stanford University

Class: ME 104 - Mechanical Systems Design - Winter 2025

Length: 3 Weeks

Materials: 3D Printed PLA

Skills: CAD/Fusion 360, Structural Analysis, Finite Element Design (FEA), Design for Mass Efficiency, Additive Manufacturing, Iterative Prototyping, Performance Testing

Type: Individual Project

Goals: Designing, analyzing, 3D-printing, and testing a lightweight structural PLA component that fits within specific geometric constraints, withstands a ≥ 200 N load with ≤ 0.010 m deflection, and is optimized for mass efficiency.

Why?

To design and optimize a lightweight, high-strength structural component under strict geometric, load, and material constraints

To strengthen skills in mechanical analysis, CAD/FEA simulation, and iterative prototyping through design, 3D printing, and performance testing

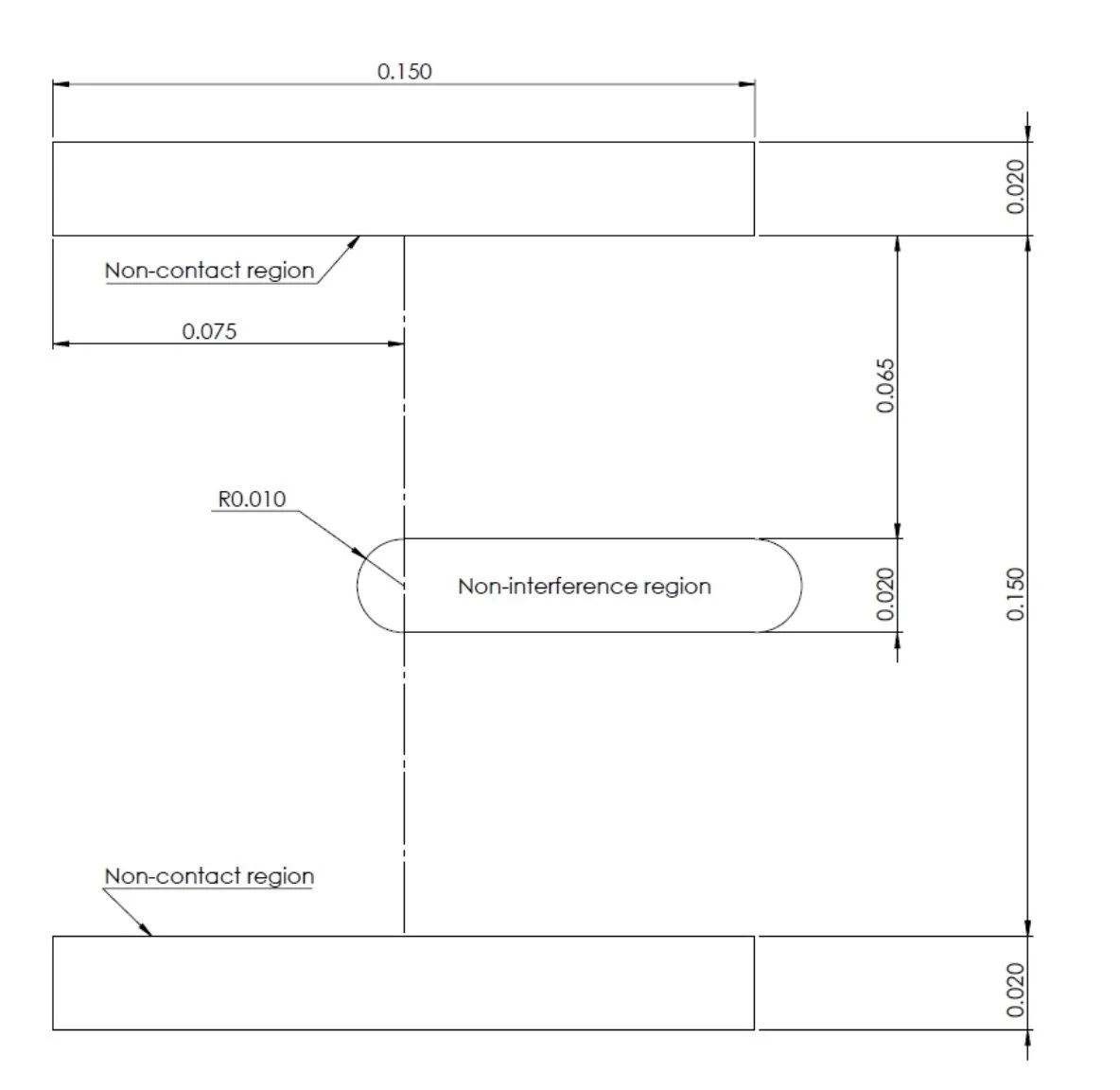

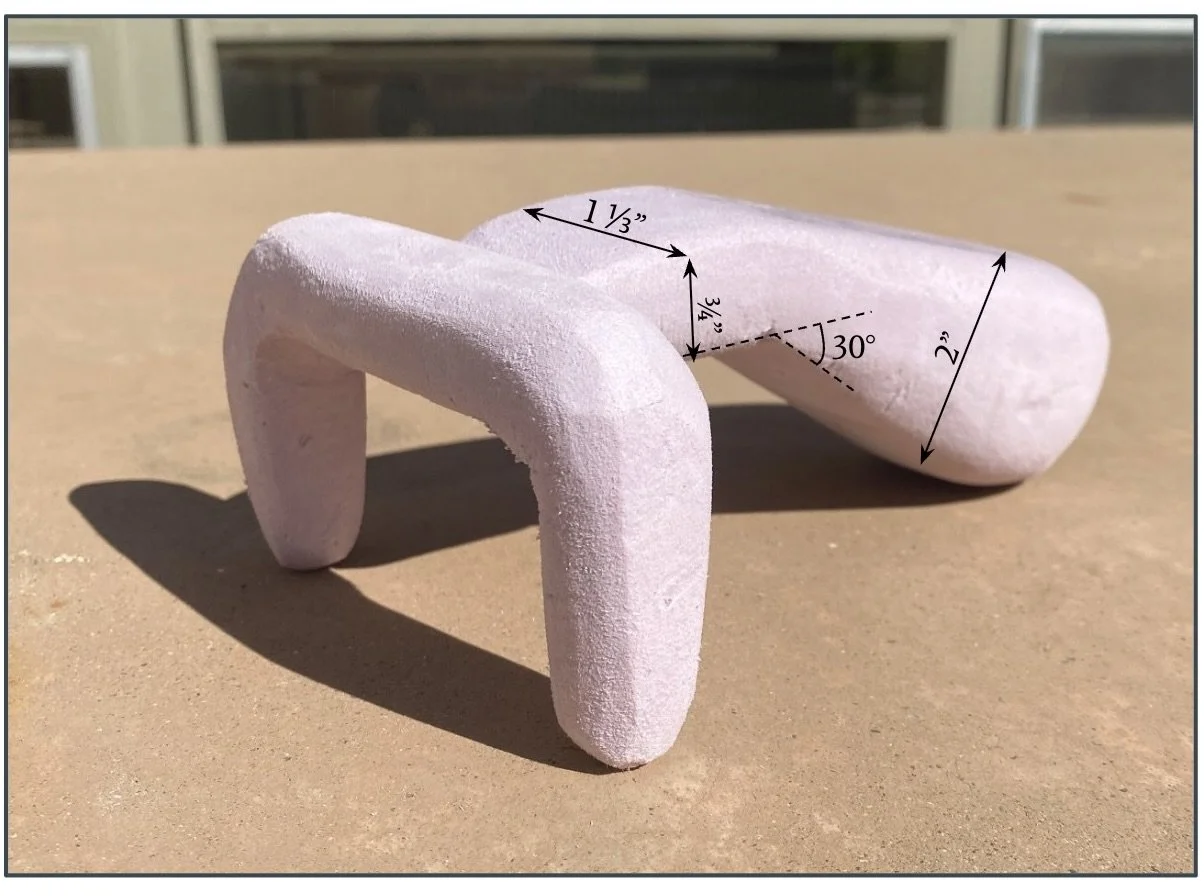

Constraints:

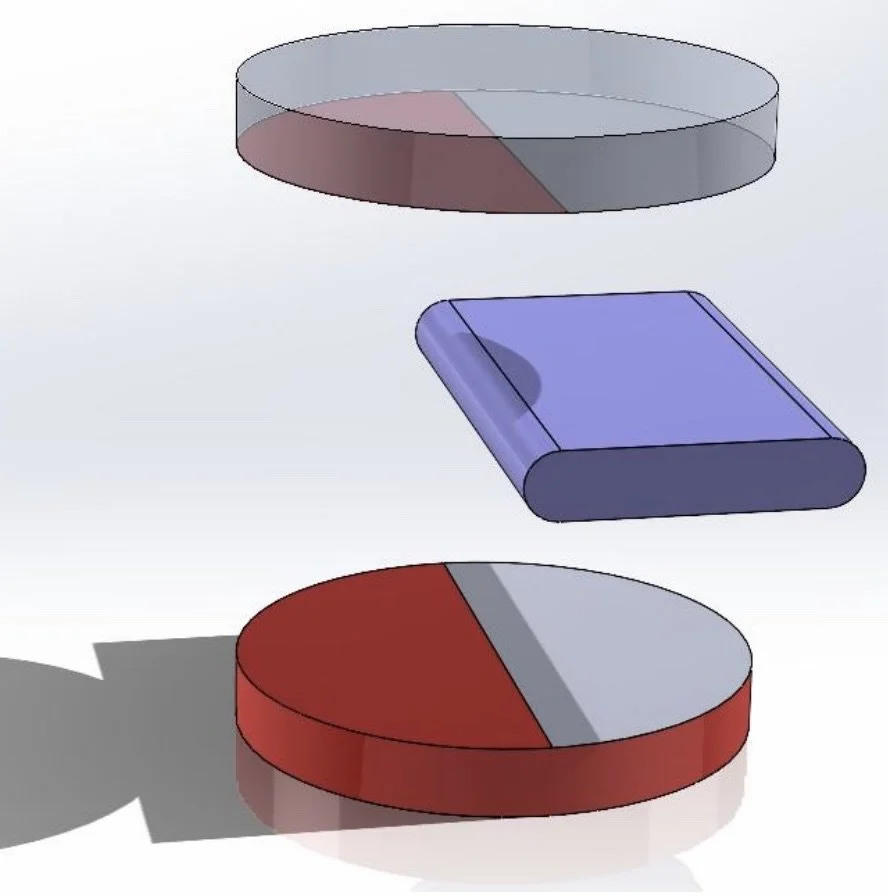

Candidate Shape

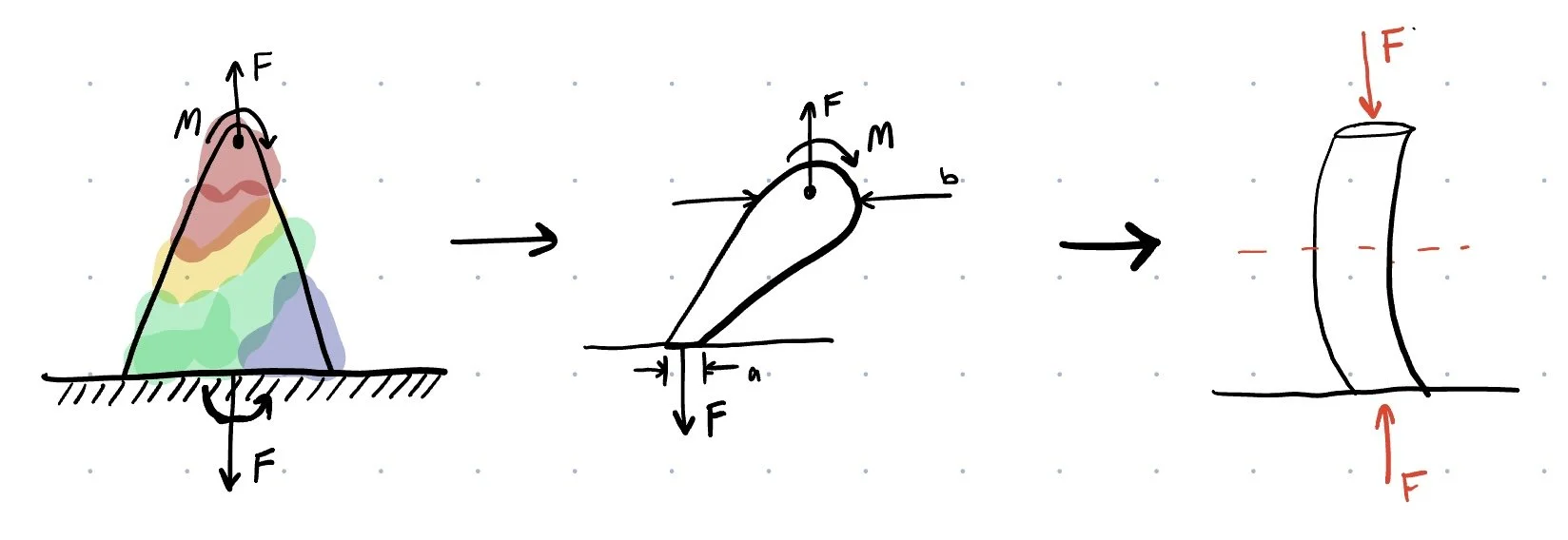

Free Body Diagrams

Wants

Thicker build when the Moment increases in the middle of the structure

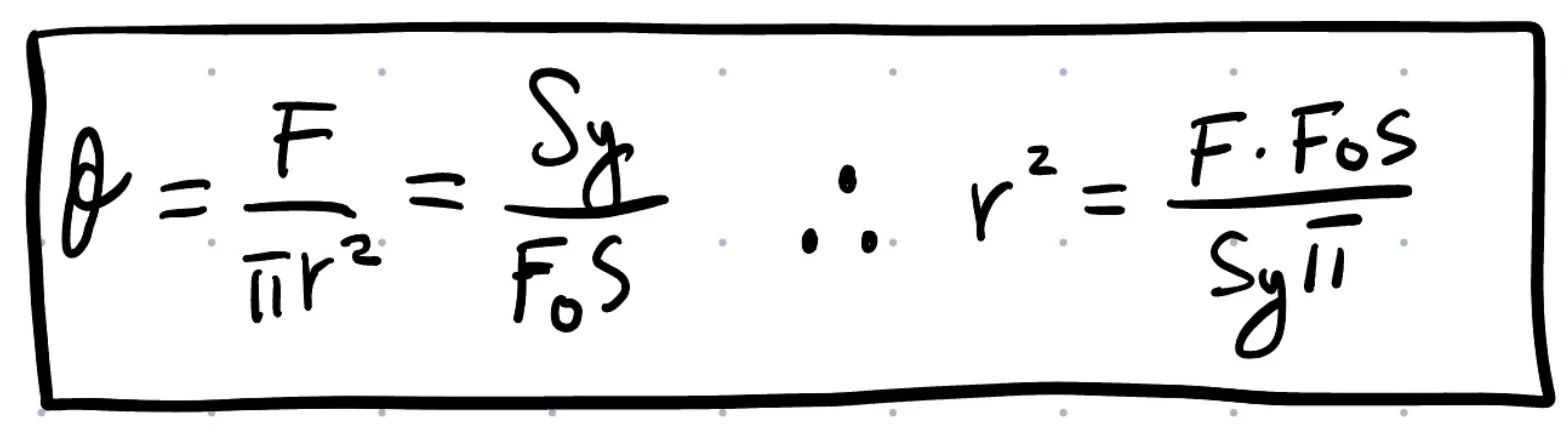

Axial Stress Analysis and Inverse

Shows that the larger the radius, the smaller the axial stress

Most concerned about bending and buckling analysis

Analysis:

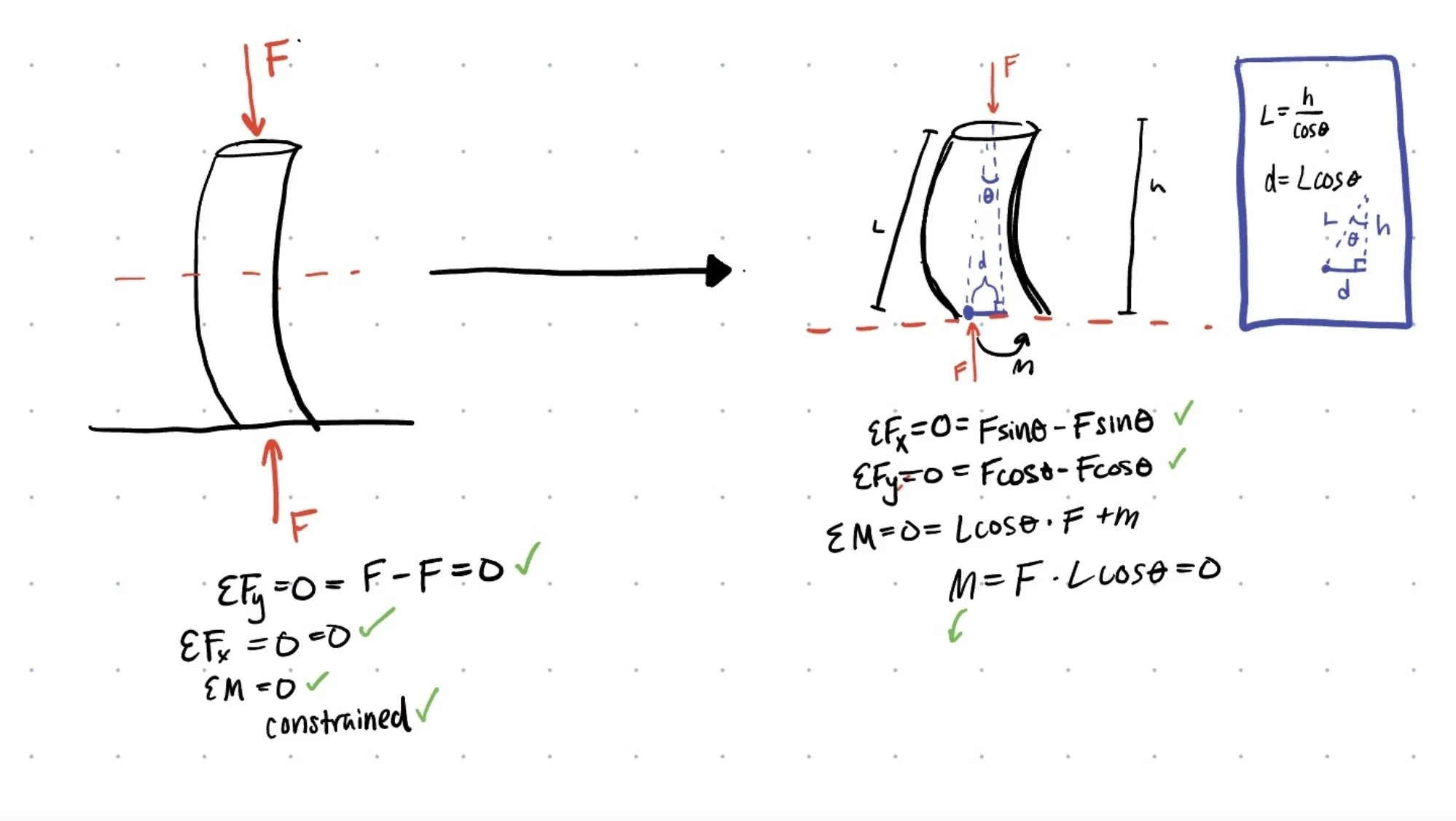

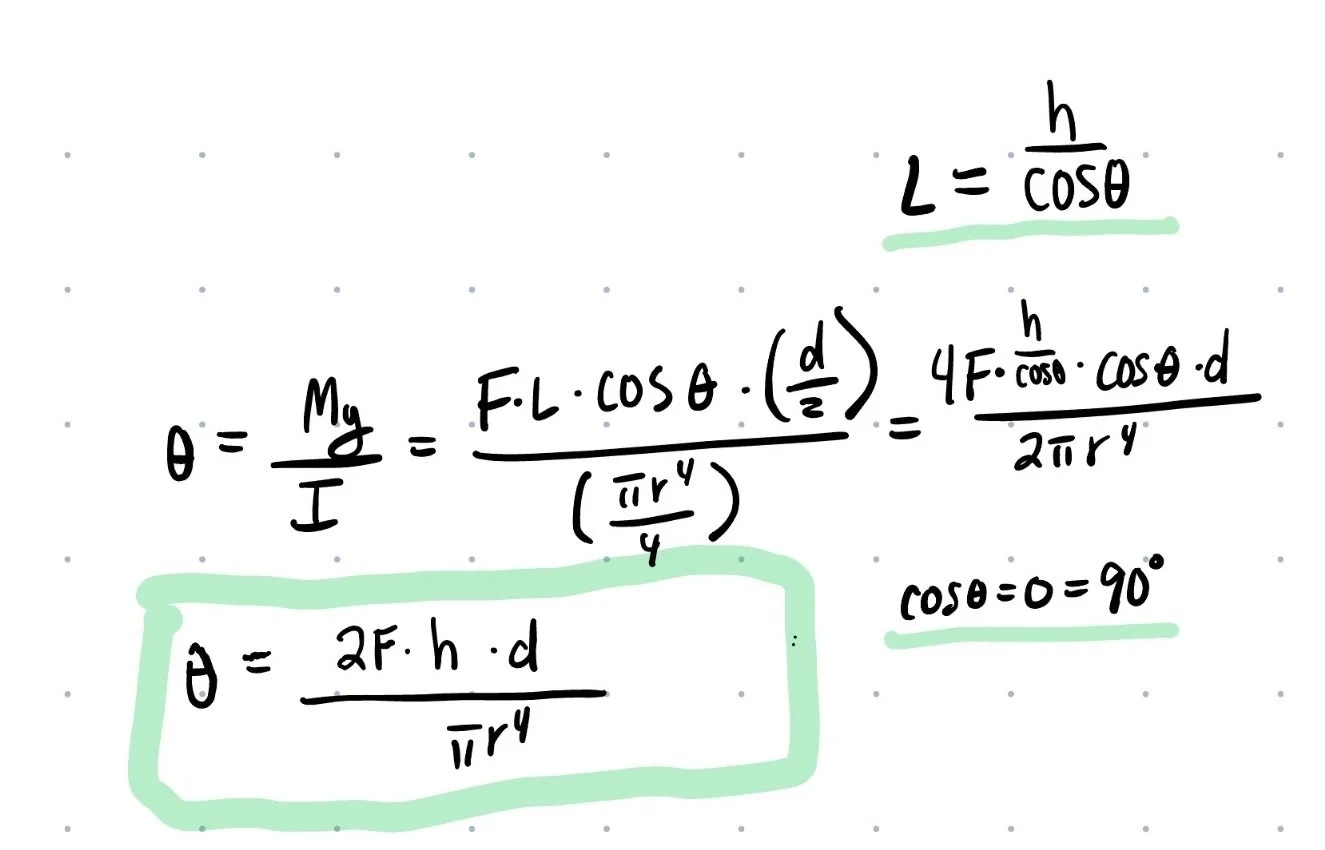

Bending Stress Analysis

Shows that theta needs to be as close to 90 degrees as possible for least amount of buckling

Analysis:

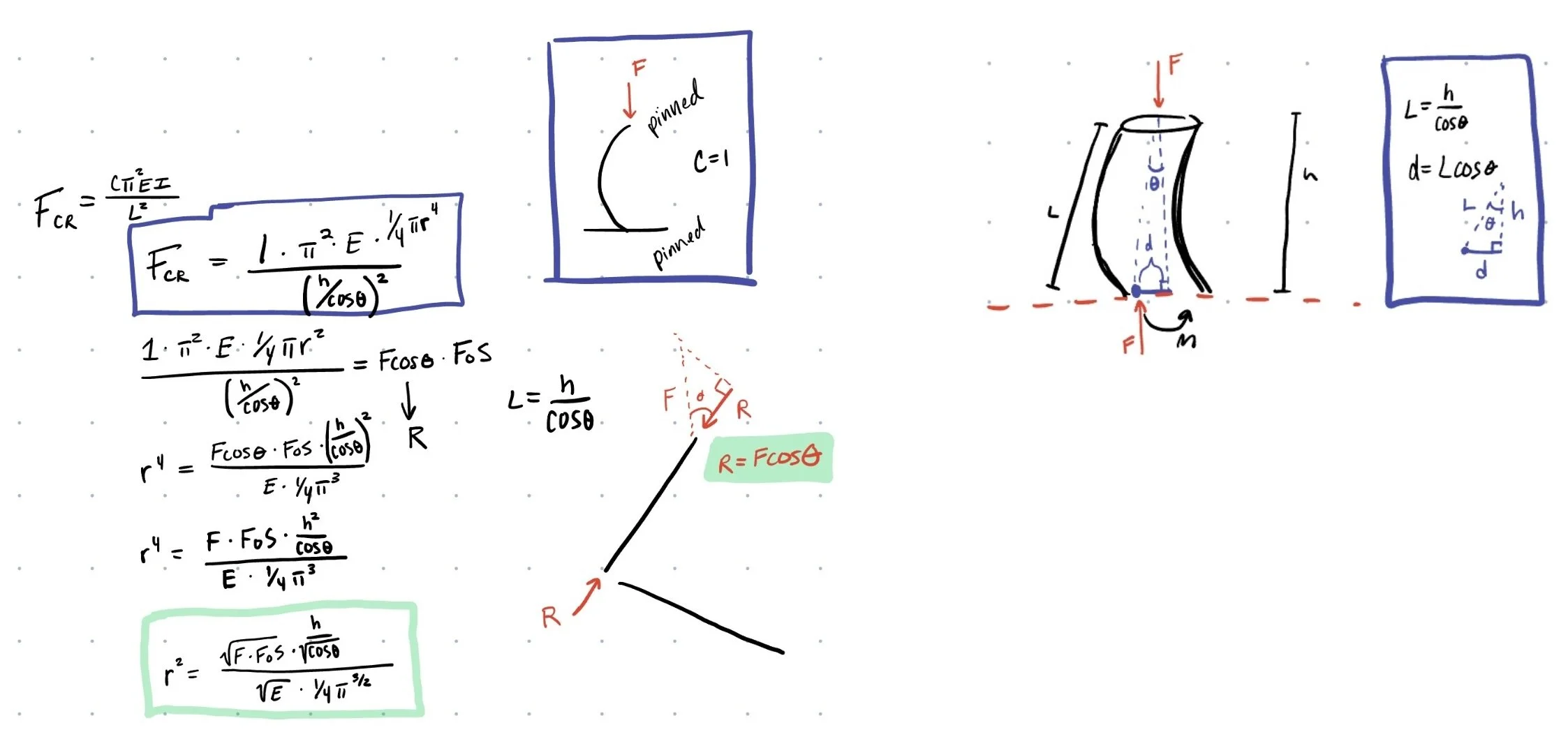

Buckling Stress Analysis and Inverse

By inverting Euler’s buckling equation, this analysis links load requirements, geometry, and material properties to the minimum radius needed for stability — ensuring the design resists buckling with an appropriate factor of safety while remaining mass-efficient

Analysis:

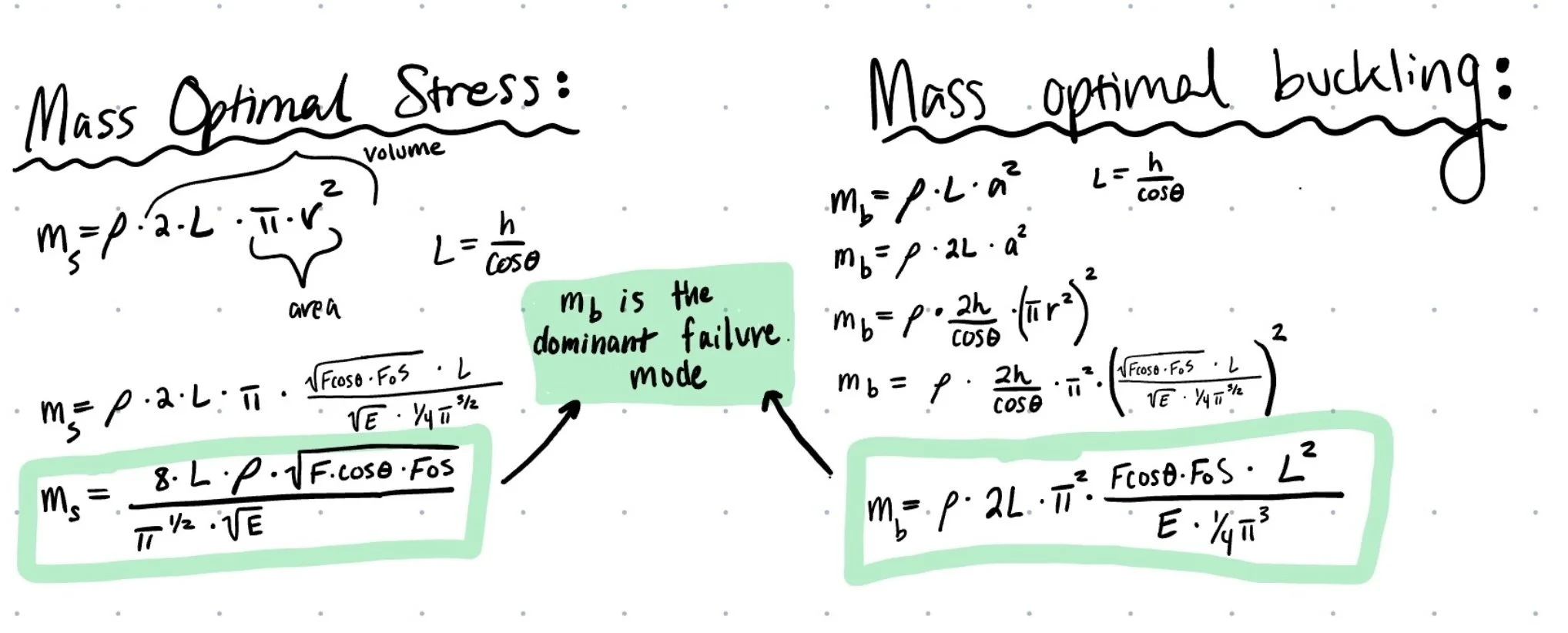

Mass Optimal Stress & Buckling

Mass optimal buckling is the dominant failure mode

Analysis:

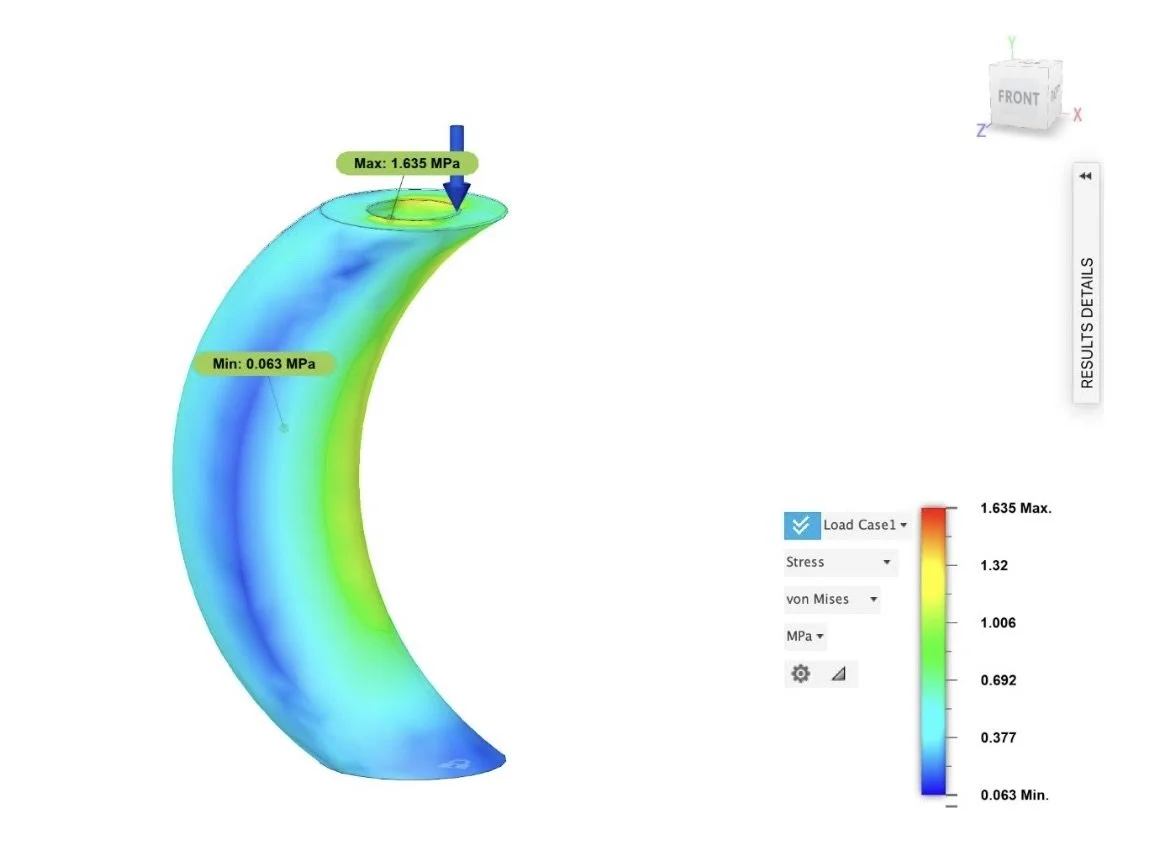

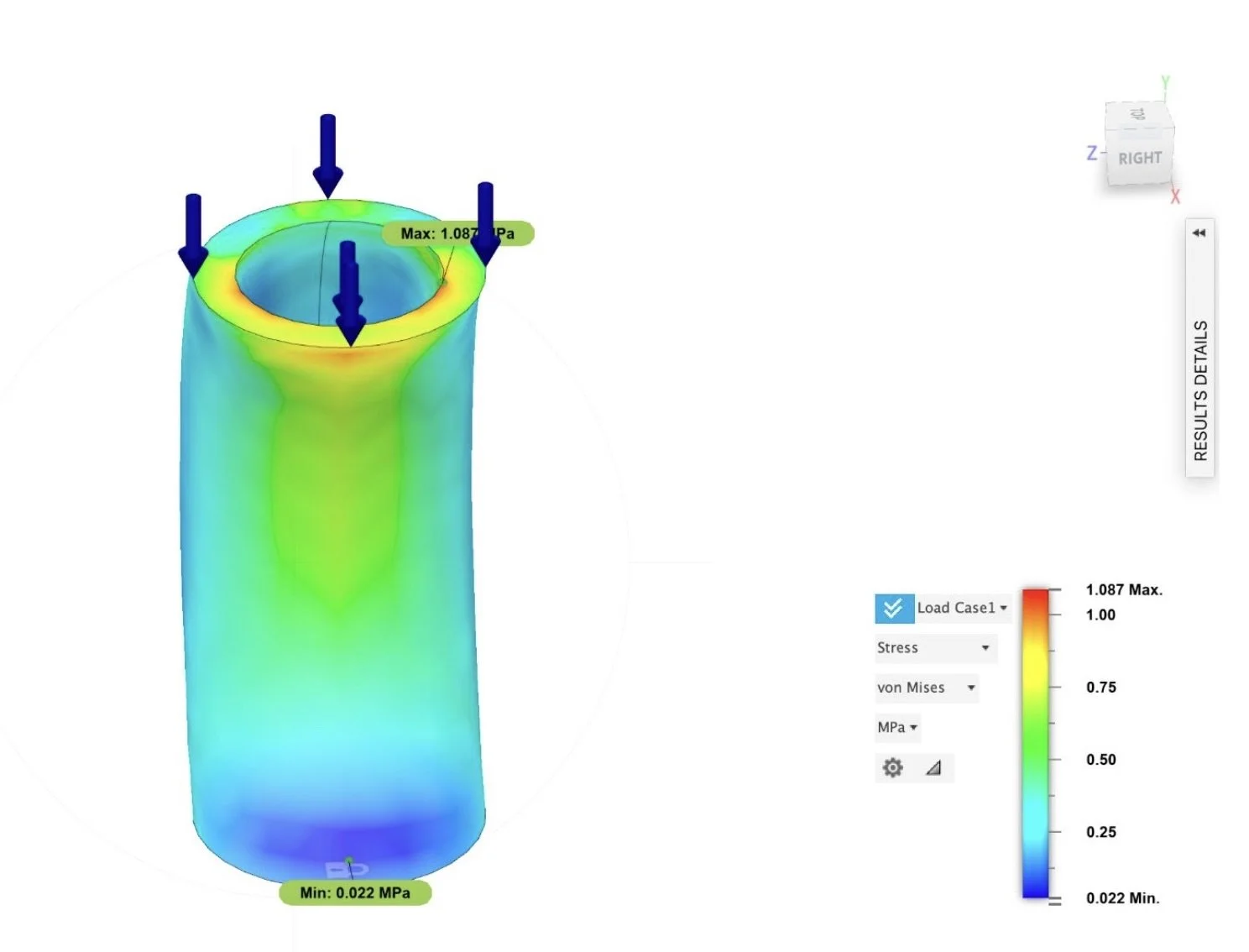

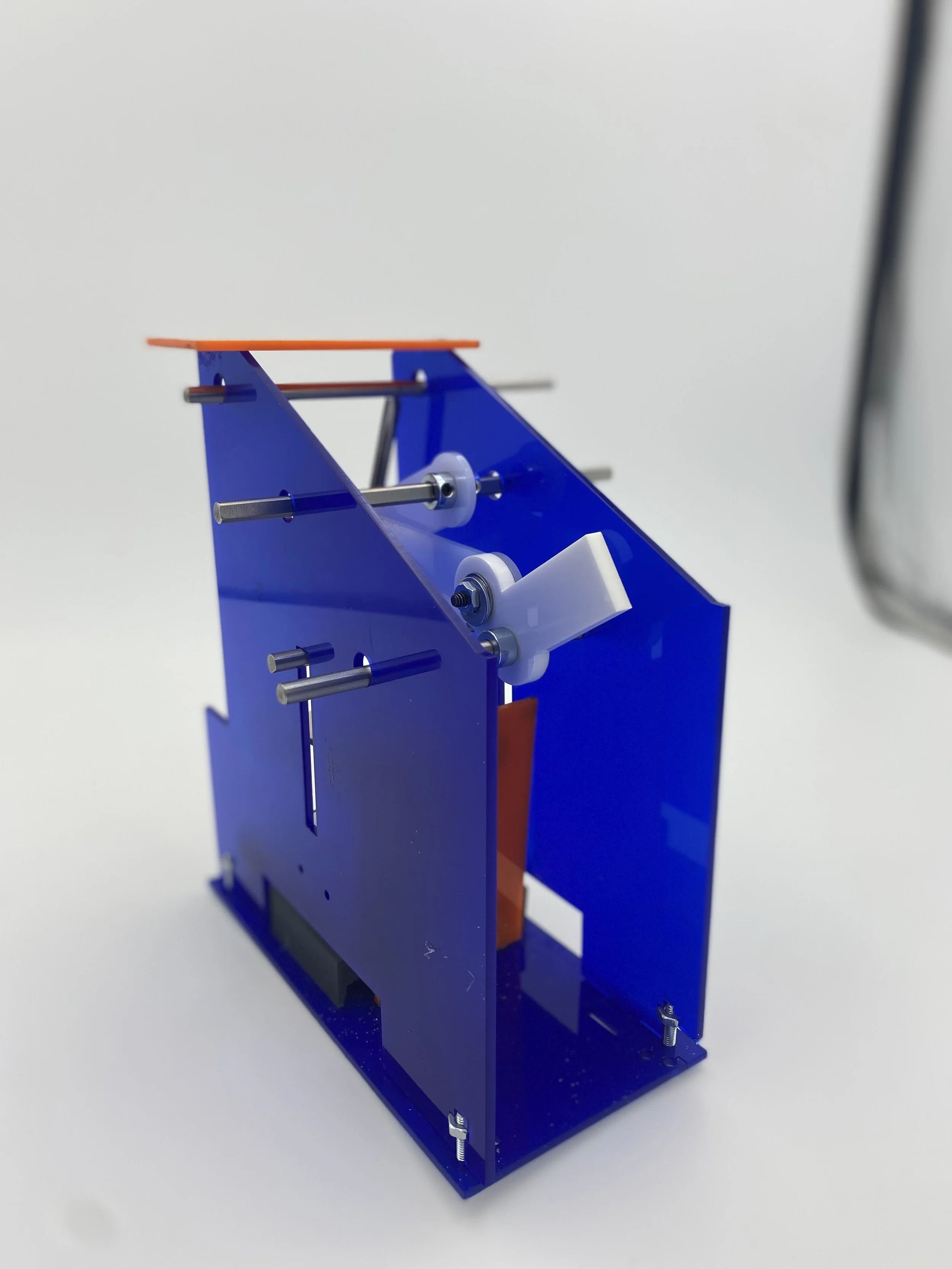

FEA Analysis

5 cm outer diameter

2.5 cm inner diameter

7.5 cm outer diameter

5 cm inner diameter

More stress/less evenly distributed

Summary:

Add mass in the middle

Shrink the radius of the ends

Make theta as close to 90

Keep the tube/cylindrical shape /no corners

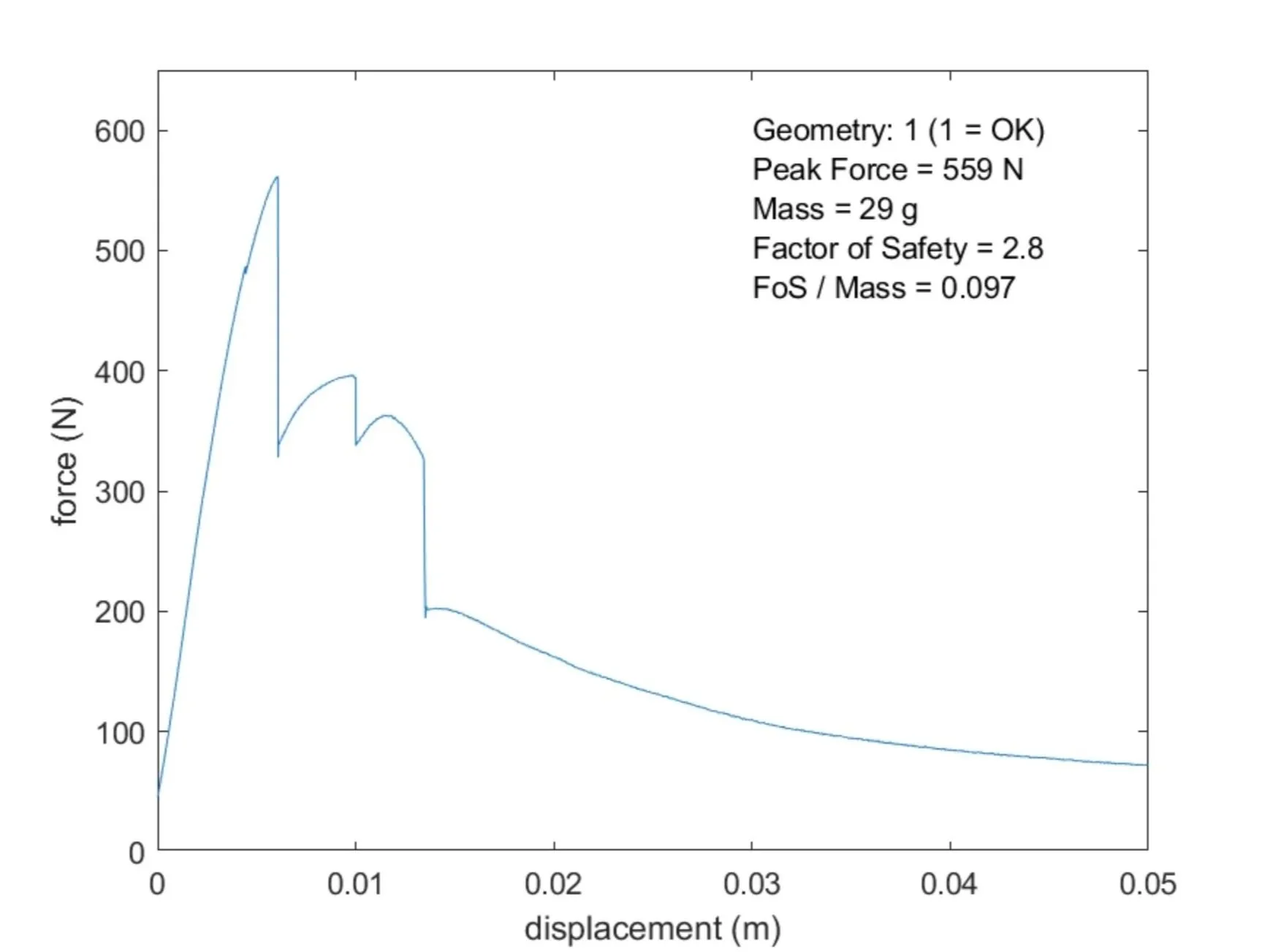

Testing Day

Passed!

Alterations for next time:

Further minimize mass